Introduction:

Suppositories are solid

dosage forms of various sizes, appearance (shapes) and weights intended for

administration commonly by rectal route, vaginal route or even urethral where

they melt, soften or dissolve to exert their effect. Suppositories come in

variety of sizes and shapes where they are capable of being easily inserted

into the intended orifice without causing undue distention. Moreover,

suppositories can be used for two main purposes. The first is to act locally as

a protective around the tissue where it is inserted and on the other hand

suppository can not only act simply as a vehicle or carrier of an active drug,

that we want to be absorbed at site of action but it can also be distributed

systematically to produce an effect throughout the entire body.

The suppository usually

composed of a medicament incorporated (dissolved or suspended) in a suppository

base, this medicament may be intended for retention within the cavity for

localized drug effect or to be absorbed for the exertion of systemic effect.

For example, rectal localized action such as relief of constipation, pain,

itching and inflammation associated with hemorrhoid conditions. Suppositories

are indicated for systemic action in pediatric patients and in patients who

cannot take or tolerate oral medication due to variety of reasons e.g. to

relief nausea, vomiting and pain. The drug must be spread in a suitable base of

suppository. Ideal suppository bases should be easily formed by compression or

molding; release any medicament readily; melt at body temperature or dissolve

or disperse in body fluids; keep its shape when handled; compatible with the

drugs, non-irritant and non-toxic.

Polyethylene glycol

(PEG) polymers have received much attention as suppository bases in recent

years because they possess many desirable properties. They are chemically

stable, non-irritating, miscible with water and mucous secretions, and can be

formulated, either by mold or compression, in a wide range of hardness and

melting point. Moreover, they do not melt at body temperature, but dissolve to

provide a prolonged release. Certain PEG polymers may be used singly as

suppository bases but, more commonly, formulas call for compounds of two or

more molecular weights mixed in various proportions as needed to yield a

finished product of satisfactory hardness and dissolution time.

Objectives:

·

To calibrate

suppository mould with PEG before preparing medicated suppositories.

·

To determine the

effect of different compositions of PEG base on the physical characteristics of

suppositories.

3.0 Materials and

methodology:

3.1 Apparatus:

|

·

Water bath at 37oC

|

·

1 x Suppository mould set

|

|

·

Hotplate

|

·

1 x Spatula

|

|

·

4 x 50 mL beaker

|

·

4 x Weighing boats

|

|

·

1 x 5 mL pipette and pipette

bulb

|

·

2 x Glass rod

|

|

·

1 x 5 mL measuring cylinder

|

·

Analytical balance

|

3.2 Materials:

|

·

Polyethylene glycol (PEG) 1000

|

·

Distilled water

|

|

·

Polyethylene glycol (PEG) 6000

|

·

Liquid paraffin

|

|

·

Paracetamol

|

|

3.3 Methodology

3.3.1 Calibration of

Suppository Molds with PEG Base

For the calibration

exercise, 10 g of following proportion PEG 1000 and PEG 6000 had been used.

|

Ingredients

|

Percentage

|

Weight Basis

|

|

PEG 1000

|

60%

|

6.00 g

|

|

PEG 6000

|

40%

|

4.00 g

|

To calibrate the mold

with PEG suppository base:

1. A clean and dry mold

is taken and the mold is not lubricated.

2. The PEG 1000 is

melted on a steam bath or hot plate, then, the heat is reduced and mixed with

other PEG.

3. The mixture is

removed from the heat and is allowed to cool before pouring into the mold.

4. The cavities are

overfilled in the mold and is left to solidify at room temperature.

5. The excess is

carefully removed with a hot spatula; the suppositories were removed from the

mold.

6. The suppositories

are weighed and the total weight is recorded. The average suppository weight is

calculated.

3.3.2 Preparation of

paracetamol suppositories

1. Saturated stock

solution of paracetamol is prepared by adding 10 g of paracetamol in 5 mL

distilled water.

2. Paracetamol

suppository is prepared using the following formulation:

|

Suppository

|

PEG 1000

(g)

|

PEG 6000

(g)

|

Paracetamol

stock solution (mL)

|

Total

(g)

|

|

I

|

9

|

0

|

1

|

10

|

|

II

|

6

|

3

|

1

|

10

|

|

III

|

0

|

9

|

1

|

10

|

3. Each type of PEG is

melted on the steam bath or hot plate, then, the heat is reduced and mixed with

other PEG.

4. The mixture is

removed from heat and is allowed to cool down before pouring into the mold.

5. The cavities are overfilled in the mold and is

left to solidify at room temperature.

6. The excess is

carefully removed with a hot spatula; the suppositories were removed from the

mold.

7. The shape, texture

and colour of the suppositories are observed.

8. Each of the suppositories are put into separate

beaker containing distilled water ( 10 mL and pre-warmed at 37 oC) and the beaker is put into the water bath.

9. The time for

the suppositories to melt is recorded.

Results:

Calibration of suppository molds with PEG base.

|

Mold

|

|

|

Total

weight for 6 suppositories

|

6.457

g

|

|

Average

weight for 1 suppository

|

1. 076g

|

|

Suppositories

|

I

|

II

|

III

|

|

Time taken to melt

(min)

|

47.34

|

42.11

|

54.48

|

|

Shape

|

Bullet

|

Bullet

|

Bullet

|

|

Hardness

|

Low

|

Medium

|

High

|

|

Greasiness

|

High

|

Medium

|

Low

|

|

Color

|

Clear White

|

Clear White

|

Pale White

|

Discussion :

1. Describe the important of

calibrating suppository mould before preparing medicated suppository

The

calibration of suppository mould is required to be done as each individual mold

is capable of holding a specific volume of material in each of its openings.

For example, the weight of suppository made up of cocoa butter will differ from

the weight of suppository prepared in the same mold with a polyethylene glycol

base (PEG) due to the differences in the density of the base materials.

Therefore, any addition of medicinal agents alters the density of the base and

the weight of the resulting suppository will differ from the suppository that

has been prepared with base material alone. This is the reason why a

pharmacists calibrates the suppository mold with a common base; to ensure that

the medicated suppository will contain proper amount of medicament.

2. Compare the physical appearance of suppositories that are formed and

discuss.

The shape for all Paracetamol

suppositories are bullet shape because they are made using the same mold. The

higher the molecular weight, the more hydroxyl group, the higher its melting

point. As a result, the melting point for suppository III, which has 9g of PEG

6000,

is the longest and supposedly the melting point point for suppository I is the

fastest but somehow our result deviate because suppository II melt faster. This could be due to error while conducting

this experiment. The same relationship

can be used to explain the hardness of the suppositories, the more amount of

PEG 6000 the harder

the suppository will be.. Suppository I is more greasy than the

other suppositories because it contain 9g of PEG 1000. PEG 1000 is more hydrophobic than PEG 6000 so, the higher

amount of PEG 1000, the more greasy the suppository will be.

3.

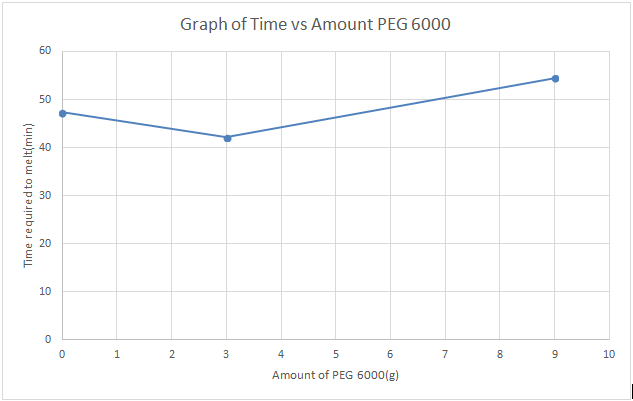

From the graph,it is known that suppositories that have

higher amount of PEG 6000 melt less rapidly than others suppositories using

lesser amount of PEG 6000.This can be attributed to the physical properties of

the suppositories itself, suppositories having high amount of PEG 6000 exhibit

increase hardness and brittle properties,which upon contact with water or

aqueous solution,disintegrate more easily than those suppositories having lower

amount of PEG 6000 and appear soft.

4. Describe function(s) of each ingredients used

in the suppository formulation.

The ingredients used in the suppository formulation is

PEG 1000, PEG 6000 and paracetamol. Paracetamol is the active ingredient in the

suppository. Paracetamol is also known as acetaminophen. It has analgesic

effect and antipyretic effect. It can help to relieve pain and fever. It is

typically used for mild to moderate pain.

Polyethylene glycols are polymers of ethylene oxide and

water which has various chain lengths, molecular weights, and physical states.

They are chemically stable, nonirritating, and miscible with water and mucous

secretions and can be formulated, either by molding or compression, in a wide

range of hardness and melting point. The higher the molecular weight of PEG,

the harder the suppositories formed and the higher the melting point.. Certain

polyethylene glycol polymers may be used singly as suppository bases but, more

commonly, two or more PEG with different molecular weights are used to yield a

finished product of satisfactory hardness and dissolution time.

Since

PEG is a water miscible bases, the suppository will dissolve in body fluids and

thus, need not to be formulated to melt at body temperature. Hence, it can be

formulated with much higher melting points and thus may be safely stored at

room temperature. Formulation with higher amount of PEG 6000 compare to PEG

1000 will take a longer time to melt completely and thus, has slower release

rate of drug.

Conclusion

As a conclusion, different composition in the

suppository will affect the physical property and the rate of drug release from

the suppository. Higher amount of PEG 6000, the more harder the suppository and

the higher its melting point.