TITLE :

Characterisation of Emulsion Formulations

OBEJCTIVES :

To determine:

1. The effects of HLB surfactant on the stability of

the emulsion.

2. The effects of different oil phases used in the

formulation on the physical characteristics

and stability of the emulsion.

INTRODUCTION :

Emulsion can be defined as a

disperse system consisting two immiscible liquids where one is dispersed as

droplets in another. The liquid droplets are also known as disperse or internal

phase, while the liquid in which they are dispersed is called continuous or

external phase. The disperse phase or continuous phase of pharmaceutical emulsion are usually water and

oil.

Emulsions are thermodynamically

unstable system due to high surface tension between two phases. Generally,

emulsion can be categorised as oil-in-water emulsion (o/w) and water-in-oil

emulsion (w/o). It is stabilised by adding emulsifying agents. Hydrophile - lipophile

balance or HLB method is used to determine the quantity and type of surfactant

that is needed to prepare stable emulsion. The number 1 to 20 is assigned to

each surfactant to express numerically the size and strength of the polar

portion relative to the non-polar portion of the molecule. Usually combinations

of two emulsifying agents are used to form a more stable emulsion. HLB value

for a combination of emulsifying agents can be determined by using the

following formula:

Apparatus and materials

a. Apparatus

1.

8 test tubes 9.

1 set of 5ml pipette and bulb

2.

A 50 ml

measuring cylinder 10.

1 5ml beaker

3.

2 sets of

pasture pipettes and droppers 11. A

15ml centrifugation tube

4.

Vortex mixer 12.

Centrifugation apparatus

5.

Weighing

boat 13.

Viscometer

6.

1 set of mortar

and pestle 14.

Water bath (45oC)

7.

Light microscope 15. Refrigerator

8.

Microscope

slides

b. Materials

1.

Palm oil

2.

Arachis oil

3.

Olive oil

4.

Mineral oil

5.

Distilled water

6.

Span 20

7.

Tween 80

8.

Sudan III

solution

PROCEDURES :

1.

Each test tube labelled

and 1cm from the base of the test tube is marked.

2.

4ml of oil (according to table 1) and 4ml of

distilled water is mixed into the test tube.

(Table

1)

Group

|

Oil

|

1, 5

|

Palm

oil

|

2, 6

|

Arachis

oil

|

3, 7

|

Olive

oil

|

4, 8

|

Mineral

oil

|

3.

Span 20 and

Tween 80 is added into the mixture of oil and water (refer to table 2). The

test tube is closed and its content is mixed with vortex mixer for 45 seconds.

The time needed for the interface is recorded for the interface to reach 1cm.

The HLB value is determined for each sample. The steps 1 to 3 is repeated to

obtain an average HLB value of a duplicate.

(Table 2)

Tube no.

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

Span 20

(drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

Tween 80

(drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

4.

A few drops of

Sudan III solution is added to (1g) emulsion formed in a weighing boat and is

mixed homogenously. The spread of the colour in the sample is compared. Some of

the sample is spread on the glass slide and observed under the light

microscope. The appearance and globule size formed is drawn and described.

5.

A Mineral Oil

Emulsion (50ml) is prepared from the formulation below using wet gum method

according to table 3a & 3b.

(Table 3a)

Mineral oil

|

(Refer to table 3b)

|

Acacia

|

6.25 g

|

Syrup

|

5 ml

|

Alcohol

|

3 ml

|

Vanillin

|

2 g

|

Distilled water qs

|

50 ml

|

(Table 3b)

Emulsion

|

Group

|

Mineral oil (ml)

|

I

|

1, 5

|

20

|

II

|

2, 6

|

25

|

III

|

3, 7

|

30

|

IV

|

4, 8

|

35

|

6.

40g of emulsion

is placed into a 50 ml beaker and is homogenized for two minutes using a vortex

mixer.

7.

2g of emulsion

is taken (before and after homogenization) and is placed into a weighing boat

and labelled.

8.

The viscosity of

the emulsion formed after homogenization (15g in 50ml beaker) is determined

using a viscometer that is calibrated with ‘Spindle’ type LV-4. The sample is

exposed to 45oC (water bath) for 15 minutes and then to 4oC

(refrigerator) for another 15 minutes. After the exposure to the temperature

cycle is finished and the emulsion had reached room temperature (10-15minutes),

the viscosity of the emulsion is determined. Step 8 is repeated and an average

value is obtained.

9.

5g of homogenised emulsion is placed into a centrifugation tube and

centrifuged (4500 rpm, 10 minutes, 25oC). The height of separation

formed is measured and the ratio of height separation is determined.

RESULT :

VISCOSITY

Group 1/5

Readings

|

Viscosity (cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature cycle

|

42

|

42

|

36

|

24

|

30

|

24

|

33

|

After temperature cycle

|

48

|

45

|

40

|

30

|

38

|

36

|

39.5

|

Difference (%)

|

19.70%

|

||||||

Group 2/6

Readings

|

Viscosity (cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature cycle

|

276

|

288

|

264

|

294

|

342

|

290

|

292.3

|

After temperature cycle

|

318

|

330

|

330

|

306

|

312

|

314

|

318.3

|

Difference (%)

|

8.90%

|

||||||

Group 3/7

Readings

|

Viscosity (cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature cycle

|

12

|

18

|

12

|

18

|

12

|

18

|

15

|

After temperature cycle

|

54

|

42

|

42

|

42

|

42

|

36

|

43

|

Difference (%)

|

186.70%

|

||||||

Group 4/8

Readings

|

Viscosity (cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature cycle

|

3.6

|

3.9

|

6.9

|

3.9

|

18.3

|

17.1

|

9.0

|

After temperature cycle

|

14.4

|

19.2

|

10.8

|

8.4

|

7.2

|

8.4

|

11.4

|

Difference (%)

|

26.70%

|

||||||

Average Viscosity (cP)

|

Amount of mineral oil (ml)

|

|||

20

|

25

|

30

|

35

|

|

Before temperature cycle

|

33

|

292.3

|

15

|

9.0

|

After temperature cycle

|

39.5

|

318.3

|

43

|

11.4

|

Differences

|

19.70%

|

8.90%

|

186.7%

|

26.7%

|

Mineral Oil(ml)

|

Height of separation

formed(cm)

|

Average(x)

|

Ratio of

separation(y)

|

||

20

|

4.0

|

3.5

|

4.0

|

3.83

|

0.77

|

25

|

3.0

|

3.50

|

3.30

|

3.27

|

0.66

|

30

|

3.3

|

3.3

|

3.2

|

3.3

|

3.3/4.7=0.70

|

35

|

0.45

|

0.45

|

0.43

|

0.43

|

0.43

|

DISCUSSION :

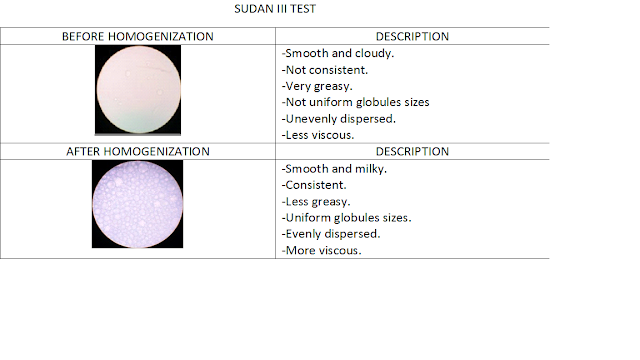

PHYSICAL APPERANCES OF OLIVE OIL EMULSIONS AND COLOUR DISPERSION PRODUCED BY SUDAN III AND SUDAN III TEST

Based on the experiment conducted by using olive oil, it happens that before homogenization the emulsion is unstable because the oily phase is immiscible with aqueous phase. The globules appear in different sizes and more large through microscope. They are unevenly being dispersed.

But after homogenization, the emulsion had become more stable as it has become less oily and has more viscosity. The globules are much smaller and evenly distributed.

VISCOSITY

Oil

is more viscous than water. Hence, theoretically, when the amount of mineral

oil increases, the viscosity of the emulsion will increases. From the

experiment, before the temperature cycle, we can see that the viscosity of

emulsions fluctuate when the amount of mineral oil increase. The emulsion with

25ml of mineral oil has the highest viscosity which is 292.3 cP while the one

with 35ml of mineral oil has the lowest viscosity which is 9.0 cP. This may be

due to some error during the experiment and the use of different viscometer.

Theoretically, the viscosity should have increased from the emulsion with

lowest amount of mineral oil to the highest.

When

the temperature increases, the viscosity of emulsion decreases. The oil

globules gain more kinetic energy and can collide with each other more

frequently. This may results in coalescence and breaking of the emulsion. While

at low temperature, the kinetic energy of oil globules reduces. The viscosity

of the emulsion will increase and it is harder for the oil globule to collide

with each other and reduces the chances for coalescence. Hence, emulsion is

more stable at low temperature. Thus, after the temperature cycle, the

viscosity of the emulsion increases. Theoretically, the difference of viscosity is directly proportional to the amount of

oil. Due to the error in the experiment, all four emulsions showed increase in

the viscosity after temperature cycle but the increase is not proportional to

the amount of mineral oil.

CONCLUSION :

1)

Different types of suspension will have

different viscosity.

2)

Based on this experiment, it can be concluded

that by using olive oil, emulsion can be stabilized after homogenization. It is

less oily and more viscosity.

3)

The more viscous, the emulsion will be more

stable.

4)

Hypothesis made is accepted.